Established in 1964, Bianchi Casseforme Srl, designs, manufactures and commissions plant machinery for the precast concrete industry. Their product range includes:

Bianchi Casseforme

- Moulds/Forms for all types of precast elements e.g. industrial, commercial, civil and residential applications. This includes vertical battery moulds, tables for panels, roof and slabs, prestressed beam lines, column moulds, civil prefabrication, cabin/pods, staircase moulds, production line for housing units, ‘boundary walls’ mould system, boomerang elements moulds.

- Concrete distribution machinery/vehicles (Mobile concrete distributor Mod. Speedy & others)

- Complete precast production plants from layout design to equipment manufacture to commissioning and production start-up.

- Automatic carousel production equipment

- Magnetic systems for precast production

- Equipment for pre-stressed strands

- Lifting and fixing solutions for precast

- Vibration equipment for industrial and precast manufacture applications

Bianchi Casseforme can execute a complete turn-key project for an industrial concrete precast production plant.

Concrete Distributing Vehicles

Concrete Distribution in a Precast Plant is a key factor when measuring system efficiency. ‘Speedy’, the Concrete Distribution Vehicle engineered by Bianchi Casseforme, offers a flexible and reliable solution.

Carrying concrete directly from the batching plant to the moulds, this vehicle on wheels is conceived to satisfy all the needs concerning carriage and internal distribution of concrete. Due to its versatility and manoeuvrability, Bianchi’s ‘Speedy’ is a cost-effective solution to achieve a quick carriage process along with precise distribution of concrete into precast plants, with a quick casting cycle time and no need of external infrastructures. A single operator can transfer concrete from concrete mixing plant and the distribution into form-works is driven by a forefront arm, that can rotate 360° on a fifth wheel driven by a reduction gear. The group screw/hopper can rotate up to an angle of inclination allowing to cast up to a height in excess of 3 metres.

Based on the hopper concrete loading capacity, machines are available with the following loading capacities: 1 m³, 3-4 m³, 6 m³

Carousel/Circulation Plants

Continuous cycle production plants manufacture a varied range of precast concrete panels including single slab, double slabs, wall panels in grey, coloured or exposed aggregate finish, insulated panels, etc.

The operation cycle of the machines can be specified to the customers’ requirements in terms of plant automation starting with manually operated working stations through to a completely automated plant. The following machine types can be present in these plants:

- Production pallet

- Pallet Handling Devices

- Pallet Cleaning Machine

- Oiling Machine

- Concrete Distributor with screws or rubber belt

- Vibrating Compacting equipment

- Smoothing equipment – oscillating or vibrating levelling beam

- Finishing stations with motorised straight edge

- Shutter Robot for automatic placing and fixing of clean shutters & picking up dirty shutters

- Plotter device

- Pallet Turner for double slab production

- Pallet Stacker

- Central Shifter

- Demoulding Crane

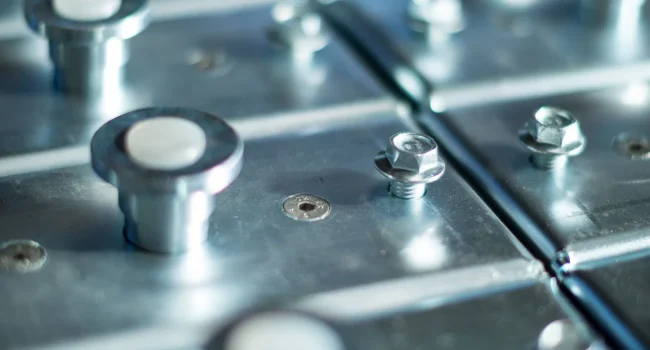

Magnetic Systems

When manufacturing flat precast concrete parts such as ceilings, walls and façade panels, efficient production equipment which guarantees dimensional accuracy and quality surfaces in exposed concrete is essential.

In cooperation with precast concrete factories, Bianchi Casseforme developed a complete magnetic formwork system, perfectly suitable for use with both wood and steel shutterings. Based on the well-known BI-BLOCK magnets, this technology meets customer requirements for accuracy, application safety, robustness and adhesive power.

Adhesion strengths range between 600kg and 2450kg.

Prestressing Equipment

The following pieces of machinery form part of Bianchi Casseforme’s prestressing equipment range:

- Strand Prestressing Hydraulic Units and Jacks

- Single-acting de-tensioning cylinders

- De-tensioning Hydraulic Units

- Pushing-Strand Machines

- Strand Sheating

- Strand Anchoring Clamps – Re-usable open-type or automatic

Lifting and Fixing Systems for Precast Concrete

Bianchi’s Quick Lifting System offers a reliable method when handling concrete elements. The connection and disconnection operations of the lifting clutch are instantaneous and allow hoisting “on edge” of panels manufactured in horizontal with speed, safety and efficiency.

Formers for spherical head anchors

Available in rubber or metal type, with rubber ring to fix the anchor head and/or with standard or magnetic fixing to the moulds

Lifting clutch

Extremely safe connection device designed for easy engagement of the spherical headed anchors whilst maintaining conformance to safety standards.

Vibration Systems for Concrete

Bianchi Casseforme manufactures its own complete range of products to generate vibration for compaction, spreading, levelling and finishing of precast concrete. This range includes:

- Fixed External Vibrators

- Sliding External Vibrators

- Double oscillating straightedge to smooth and level the concrete surface on wall panels.

- Vibrating surface straightedge for surface finishing

- Tamping vibrator designed to compact thin layers of concrete, especially useful where exposed and coloured aggregates are used.

- Needle/Pin Internal Vibrators