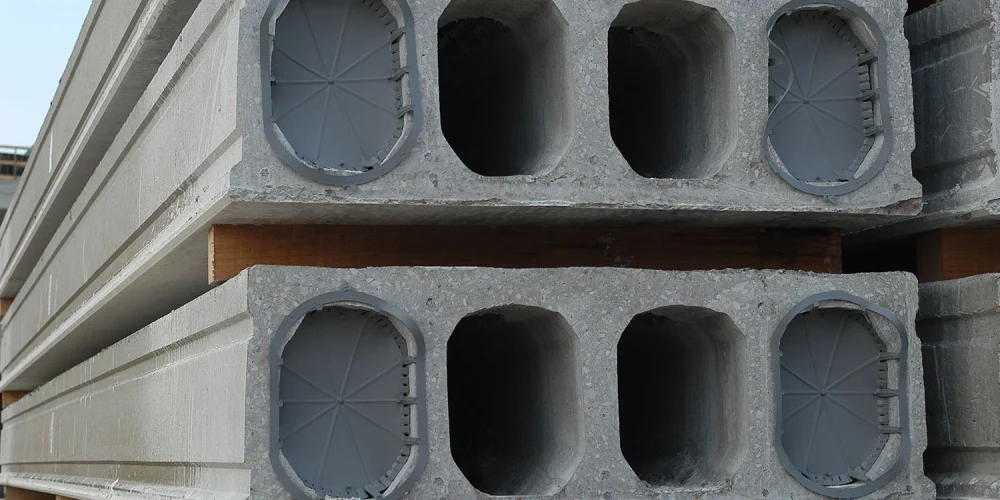

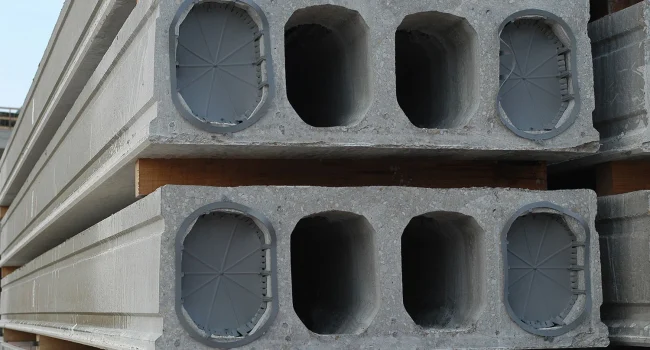

Founded in 1974, Nordimpianti is one of the world’s leading manufacturers of machines and equipment in the production of prestressed concrete elements mainly used in the construction industry. The elements are used in flooring systems or as wall panels in a wide range of residential, civil, industrial and infrastructure construction projects.

Designed and manufactured in-house at their facility near Chieti, Italy, Nordimpianti’s Extruder, Slipformer and Wet Casting technologies maintains a strong product portfolio, offering all the ancillary machines necessary to make producing elements as efficient and cost effective as possible. Their in-house consultants are available to assist with minor technical questions up to the design of complete factories, to help expand and/or refurbish existing facilities or to provide advice, support and supply of green field start up investments.

Nordimpianti is committed to product quality and service and has been driven by the desire to build and supply products of the highest quality using the latest technology available since their foundation. With a wealth of experience gained from working with global prestressed concrete producers, Nordimpianti are your reliable partner in the supply of efficient production solutions.